Hydraulic network balancing solution, HYMOD is the first decentralized module of the market designed to ensure the variable flow of secondary networks, optimizing the energy efficiency of heating or cooling systems. Particularly intended for installations up to 3000m2, HYMOD will deliver to the comfort units the flow of water best suited to each use. The HYMOD solution improves the energy efficiency of auxiliaries by up to 40%.

Faced with the tightening of the F-gas regulation on refrigerants, the solution of the water loop as heat transfer fluid becomes the natural solution for heating and refreshing buildings. Through its Hysys® system offering, CIAT now offers a complete and efficient solution for the installation of hydraulic systems. The HYMOD secondary network balancing module further optimizes this offer.

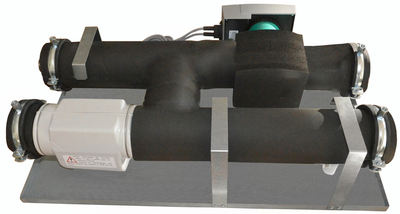

Placed between the generator (cold group or heat pump) and the transmitters (comfort units), the HYMOD modules ensure the decoupling of the primary and secondary hydraulic networks. They meet regulatory expectations on the balancing of networks and guarantee the distribution of water at the level of each transmitter. HYMOD is a guarantee of comfort, performance and conformity of the installation. It is composed of a balancing valve on the primary network, a primary bypass, and a secondary circulator with a variable flow rate from 0 to 100% depending on the needs of the emitters with low consumption motor. The HYMOD modules, positioned by tray, ensure the flow requirements up to 6 m3 / h maximum, ie a power of 35 kW.

HYMOD modules make installation easy. They are calibrated and commissioned by the CIAT teams when the entire installation is commissioned, thus releasing the installers from this task. Decentralized, they are positioned in false ceiling in each tray, and allow a significant gain in space in the technical rooms.

On the primary network side, the HYMOD decoupling module is equipped with a balancing valve to adjust the nominal flow required on the plate. This balancing at the head of the network is, moreover, imposed by article 23 of the thermal regulation RT 2012. The water supply is effected by the low pressure pump integrated in the thermodynamic machine.

On the secondary networks, the HYMOD modules are equipped with an EC circulator, ensuring the real time modulation of the water flow according to the demands of the comfort units. The variation in flow rate is ensured by a constant differential pressure management autonomously managed by the circulator. Comfort units must be equipped with self-balanced 2-way valves. When the system is switched on, they are adjusted as much as possible according to the nominal flow required for each transmitter. The pump of the module HYMOD is then parameterized to respond to the sum of these flows.

The hydraulic module HYMOD is made of stainless steel. To prevent condensation, it is equipped with a thick Armaflex insulation and special shells for the pump body and the balancing valve. An additional retention tank, secured to the piping, makes it possible to secure the device as well as possible. Together with the V30 / V300 controllers, HYMOD offers an optional change-over cabinet for transmitting the operating mode information via a pilot line to the comfort units.

Faced with the tightening of the F-gas regulation on refrigerants, the solution of the water loop as heat transfer fluid becomes the natural solution for heating and refreshing buildings. Through its Hysys® system offering, CIAT now offers a complete and efficient solution for the installation of hydraulic systems. The HYMOD secondary network balancing module further optimizes this offer.

Placed between the generator (cold group or heat pump) and the transmitters (comfort units), the HYMOD modules ensure the decoupling of the primary and secondary hydraulic networks. They meet regulatory expectations on the balancing of networks and guarantee the distribution of water at the level of each transmitter. HYMOD is a guarantee of comfort, performance and conformity of the installation. It is composed of a balancing valve on the primary network, a primary bypass, and a secondary circulator with a variable flow rate from 0 to 100% depending on the needs of the emitters with low consumption motor. The HYMOD modules, positioned by tray, ensure the flow requirements up to 6 m3 / h maximum, ie a power of 35 kW.

HYMOD modules make installation easy. They are calibrated and commissioned by the CIAT teams when the entire installation is commissioned, thus releasing the installers from this task. Decentralized, they are positioned in false ceiling in each tray, and allow a significant gain in space in the technical rooms.

On the primary network side, the HYMOD decoupling module is equipped with a balancing valve to adjust the nominal flow required on the plate. This balancing at the head of the network is, moreover, imposed by article 23 of the thermal regulation RT 2012. The water supply is effected by the low pressure pump integrated in the thermodynamic machine.

On the secondary networks, the HYMOD modules are equipped with an EC circulator, ensuring the real time modulation of the water flow according to the demands of the comfort units. The variation in flow rate is ensured by a constant differential pressure management autonomously managed by the circulator. Comfort units must be equipped with self-balanced 2-way valves. When the system is switched on, they are adjusted as much as possible according to the nominal flow required for each transmitter. The pump of the module HYMOD is then parameterized to respond to the sum of these flows.

The hydraulic module HYMOD is made of stainless steel. To prevent condensation, it is equipped with a thick Armaflex insulation and special shells for the pump body and the balancing valve. An additional retention tank, secured to the piping, makes it possible to secure the device as well as possible. Together with the V30 / V300 controllers, HYMOD offers an optional change-over cabinet for transmitting the operating mode information via a pilot line to the comfort units.