BIP Bétons, a Duroux Group company, offers a complete range of concrete products and materials for building and exterior projects. With its nine production sites, this manufacturer, which has established itself as a leader in the Greater Southwest, is constantly renewing its efforts to offer innovative, high-performance products that are easy to implement on the concrete market while at the same time Contributing to the safety and sustainability of the structures.

As proof, the opening of 2014 opens with the launch of the first window bracket with integrated thermal bridge cutter, an innovative molded concrete solution from the ÉLIBAIE® range, which guarantees a reduction of almost 50% in the thermal bridges of windows. Regardless of the type of façade. The other thresholds, including thresholds for persons with reduced mobility, supports, lintels and shutter boxes of the range, are all effective answers adapted to the challenges of designing or renovating openings in buildings: Insulation to the accessibility, passing by the aesthetic imperatives ...

100% concrete and 100% efficient solutions to discover urgently!

New concrete support with integrated insulation: thermal performance and waterproofness for lasting comfort

The thermal regulation 2012 imposes the taking into account and treatment of thermal bridges in construction or renovation projects to limit energy consumption as well as to meet user expectations in terms of comfort. Particularly involved in these new challenges, BIP Bétons has designed a range of products to effectively treat the singular points that openings represent, often causing significant thermal losses (up to 15% in the building).

The ÉLIBAIE® range now offers a new window support with integrated insulation, the innovation of which is based on the integration of the thermal bridge cutter in the molded element. The finished product thus represents an effective solution to optimize the insulation and waterproofing of the structures and simplify the implementation.

Certified by CERIB, this NF labeled solution is characterized by a rear part made of insulating material which ensures a perfect continuity of the insulation and, consequently, a reduction of the thermal bridges by 50% (compared with a standard support).

Available in 350 mm wide and 500 to 1,700 mm long (plus other lengths to order), these BIP Concrete inserts are also equipped with rear and lateral joists which support the lower part of the frame of the joinery, while evacuating Water, thus preventing the rising of moisture. Finally, to ensure a perfect seal, a natural slope to the outside of 10% ensures the drainage of rainwater.

BIP Bétons offers a true innovation adapted to current challenges in terms of thermal performance and air tightness.

Supports and thresholds ÉLIBAIE®: leading products with multiple properties ...

The range of BIP Concrete supports offers a solution with insulation integrated in width 350 mm and a solution without insulation in 280 mm wide available in lengths 500 to 1500 mm (plus other lengths on order). Equipped with a slope of 10%, these elements also have a rough underface for better adhesion of the masonry: two assets that facilitate the implementation and contribute to a better productivity.

The ÉLIBAIE® supports are certified NF, a guarantee of quality and conformity of products to the most demanding standards at present. In order to guarantee the durability of the structures, they are classified as Concrete G, a concrete formulated to withstand frost / thaw cycles.

The BIP concrete thresholds benefit from technical advantages similar to the aesthetic support and ease of implementation. Offered in widths of 280 mm (900 or 1,000 mm long) or 350 mm (lengths 900 to 2,500 mm and other lengths to order), they also offer enlarged joists for a better seating of the joinery and a slope Natural by 2%.

The PMR thresholds (Persons with reduced mobility): the accessibility of works accessible to all

With a width of 350 mm and a length of 1,000 to 1,500 mm, these thresholds are simple solutions for door-crossing or terrace access for people with reduced mobility. An integrated slope of 10% and a thickness at the end of the threshold of 38 mm making it possible to realize a jump less than 2 cm, help to facilitate the passage of the threshold. Its singular design allows it to be effective continuously: a water collector at the rear associated with lateral jets collect and evacuate the water.

The PMR thresholds are certified in conformity with the texts of the Building and Habitat Code on accessibility (Article R 111-18), giving manufacturers and end-users the opportunity to benefit from these regulatory The methods of implementation.

Aesthetic qualities contributing to the embellishment of the structure

Thus, ÉLIBAIE® solutions for the treatment of openings add to their technical performance an aesthetic character to be taken into account in construction or renovation projects. Available in gray or ivory colors, ELIBAIE® supports and thresholds adapt to the different architectural styles to equip and beautify all facades. The molded concrete gives them a perfectly smooth and homogeneous finish, enhanced by chamfered edges. A drip system spreads drip water to effectively protect the walls from unsightly staining and dirt.

Easy and safe implementation

The products of the range ÉLIBAIE® are characterized by ease of implementation, whatever their function.

After having prepared a bed of mortar on the masonry, the support or threshold element must be laid flat horizontally in order to respect the preformed slope. The reserves on each side of the installation are then clogged to bury in the masonry the lateral junctions which thus ensure the sealing with respect to the risings of moisture. A final step is to ensure the jointing of the mortar connection under the element with the masonry. The protection of the elements laid remains essential before the construction of the facade plasters.

Thermo'coffre® and Thermo'linteau®: the treatment of openings integrated into the structure

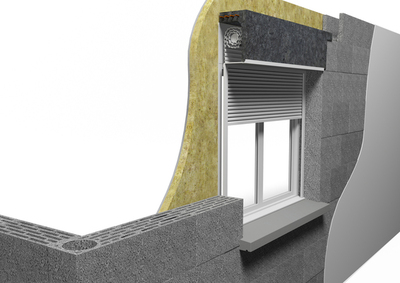

Thermo'coffre®: a dual-use formwork element

Thermo'coffre® is a non-porous formwork element 100% concrete for joinery with incorporated roller shutter. A monobloc molded concrete product, it improves the air permeability of masonry and offers the possibility of integrating insulation on the inside, thus limiting thermal bridges.

Used as a roller shutter box or as reinforced concrete prefabrication, it limits the risk of cracking of the render by guaranteeing the homogeneity of the support (RT3 support) and has the recognized acoustic attenuation capacities of the concrete. The reliability of this element has been certified in accordance with French regulations on masonry work and plaster work (DTU 20.1 and 20.6) with real energy performance (RT 2012).

There is also an interesting aesthetic dimension: by integrating the roller shutter (diameter up to 220 mm) into the thickness of the wall, the Thermo'coffre® conceals the safe inside the premises, Embellishment of habitats.

With a wide range of sizes ranging from 800 to 2 800 mm, the Thermo'coffre® is supplied as a complete kit with integrated underside and PVC cheeks, under-side support, filter brush, An aluminum profile on the underside with plaster shut-off. For ease of installation, Thermo'coffre® can be laid dry and without a forestay.

Thermo'linteau®: a long length element for a homogeneous wall

Thermo'linteau® is a horizontal U-shaped element for the production of lintels without assembly on site. With a height of 200 or 250 mm and a wide range of possible dimensions (up to 2,800 mm), it adapts to all masonry in compliance with the regulations (DTU 20.1 and 26.1).

This monolithic concrete molded lintel of the ÉLIBAIE® range guarantees the homogeneity of the masonry support, thus limiting the risk of cracking of the render (RT3 support), and also meets the seismic rules (EUROCODE 8).

Offering large spans without assembly and considerably reducing on-site cuts, these U-shaped lintels must be supported when casting for openings above 1400 mm.

BIP Concrete products are made of natural materials (94% sand, gravel, limestone, gypsum and 6% water) 100% recyclable and reusable.

The technology that contributes to their manufacture consumes little energy and requires no cooking.

In addition, with 9 production sites in the South-West, BIP Bétons offers products that contribute to the local economy and limit the CO2 footprint by reducing transport.

As proof, the opening of 2014 opens with the launch of the first window bracket with integrated thermal bridge cutter, an innovative molded concrete solution from the ÉLIBAIE® range, which guarantees a reduction of almost 50% in the thermal bridges of windows. Regardless of the type of façade. The other thresholds, including thresholds for persons with reduced mobility, supports, lintels and shutter boxes of the range, are all effective answers adapted to the challenges of designing or renovating openings in buildings: Insulation to the accessibility, passing by the aesthetic imperatives ...

100% concrete and 100% efficient solutions to discover urgently!

New concrete support with integrated insulation: thermal performance and waterproofness for lasting comfort

The thermal regulation 2012 imposes the taking into account and treatment of thermal bridges in construction or renovation projects to limit energy consumption as well as to meet user expectations in terms of comfort. Particularly involved in these new challenges, BIP Bétons has designed a range of products to effectively treat the singular points that openings represent, often causing significant thermal losses (up to 15% in the building).

The ÉLIBAIE® range now offers a new window support with integrated insulation, the innovation of which is based on the integration of the thermal bridge cutter in the molded element. The finished product thus represents an effective solution to optimize the insulation and waterproofing of the structures and simplify the implementation.

Certified by CERIB, this NF labeled solution is characterized by a rear part made of insulating material which ensures a perfect continuity of the insulation and, consequently, a reduction of the thermal bridges by 50% (compared with a standard support).

Available in 350 mm wide and 500 to 1,700 mm long (plus other lengths to order), these BIP Concrete inserts are also equipped with rear and lateral joists which support the lower part of the frame of the joinery, while evacuating Water, thus preventing the rising of moisture. Finally, to ensure a perfect seal, a natural slope to the outside of 10% ensures the drainage of rainwater.

BIP Bétons offers a true innovation adapted to current challenges in terms of thermal performance and air tightness.

Supports and thresholds ÉLIBAIE®: leading products with multiple properties ...

The range of BIP Concrete supports offers a solution with insulation integrated in width 350 mm and a solution without insulation in 280 mm wide available in lengths 500 to 1500 mm (plus other lengths on order). Equipped with a slope of 10%, these elements also have a rough underface for better adhesion of the masonry: two assets that facilitate the implementation and contribute to a better productivity.

The ÉLIBAIE® supports are certified NF, a guarantee of quality and conformity of products to the most demanding standards at present. In order to guarantee the durability of the structures, they are classified as Concrete G, a concrete formulated to withstand frost / thaw cycles.

The BIP concrete thresholds benefit from technical advantages similar to the aesthetic support and ease of implementation. Offered in widths of 280 mm (900 or 1,000 mm long) or 350 mm (lengths 900 to 2,500 mm and other lengths to order), they also offer enlarged joists for a better seating of the joinery and a slope Natural by 2%.

The PMR thresholds (Persons with reduced mobility): the accessibility of works accessible to all

With a width of 350 mm and a length of 1,000 to 1,500 mm, these thresholds are simple solutions for door-crossing or terrace access for people with reduced mobility. An integrated slope of 10% and a thickness at the end of the threshold of 38 mm making it possible to realize a jump less than 2 cm, help to facilitate the passage of the threshold. Its singular design allows it to be effective continuously: a water collector at the rear associated with lateral jets collect and evacuate the water.

The PMR thresholds are certified in conformity with the texts of the Building and Habitat Code on accessibility (Article R 111-18), giving manufacturers and end-users the opportunity to benefit from these regulatory The methods of implementation.

Aesthetic qualities contributing to the embellishment of the structure

Thus, ÉLIBAIE® solutions for the treatment of openings add to their technical performance an aesthetic character to be taken into account in construction or renovation projects. Available in gray or ivory colors, ELIBAIE® supports and thresholds adapt to the different architectural styles to equip and beautify all facades. The molded concrete gives them a perfectly smooth and homogeneous finish, enhanced by chamfered edges. A drip system spreads drip water to effectively protect the walls from unsightly staining and dirt.

Easy and safe implementation

The products of the range ÉLIBAIE® are characterized by ease of implementation, whatever their function.

After having prepared a bed of mortar on the masonry, the support or threshold element must be laid flat horizontally in order to respect the preformed slope. The reserves on each side of the installation are then clogged to bury in the masonry the lateral junctions which thus ensure the sealing with respect to the risings of moisture. A final step is to ensure the jointing of the mortar connection under the element with the masonry. The protection of the elements laid remains essential before the construction of the facade plasters.

Thermo'coffre® and Thermo'linteau®: the treatment of openings integrated into the structure

Thermo'coffre®: a dual-use formwork element

Thermo'coffre® is a non-porous formwork element 100% concrete for joinery with incorporated roller shutter. A monobloc molded concrete product, it improves the air permeability of masonry and offers the possibility of integrating insulation on the inside, thus limiting thermal bridges.

Used as a roller shutter box or as reinforced concrete prefabrication, it limits the risk of cracking of the render by guaranteeing the homogeneity of the support (RT3 support) and has the recognized acoustic attenuation capacities of the concrete. The reliability of this element has been certified in accordance with French regulations on masonry work and plaster work (DTU 20.1 and 20.6) with real energy performance (RT 2012).

There is also an interesting aesthetic dimension: by integrating the roller shutter (diameter up to 220 mm) into the thickness of the wall, the Thermo'coffre® conceals the safe inside the premises, Embellishment of habitats.

With a wide range of sizes ranging from 800 to 2 800 mm, the Thermo'coffre® is supplied as a complete kit with integrated underside and PVC cheeks, under-side support, filter brush, An aluminum profile on the underside with plaster shut-off. For ease of installation, Thermo'coffre® can be laid dry and without a forestay.

Thermo'linteau®: a long length element for a homogeneous wall

Thermo'linteau® is a horizontal U-shaped element for the production of lintels without assembly on site. With a height of 200 or 250 mm and a wide range of possible dimensions (up to 2,800 mm), it adapts to all masonry in compliance with the regulations (DTU 20.1 and 26.1).

This monolithic concrete molded lintel of the ÉLIBAIE® range guarantees the homogeneity of the masonry support, thus limiting the risk of cracking of the render (RT3 support), and also meets the seismic rules (EUROCODE 8).

Offering large spans without assembly and considerably reducing on-site cuts, these U-shaped lintels must be supported when casting for openings above 1400 mm.

BIP Concrete products are made of natural materials (94% sand, gravel, limestone, gypsum and 6% water) 100% recyclable and reusable.

The technology that contributes to their manufacture consumes little energy and requires no cooking.

In addition, with 9 production sites in the South-West, BIP Bétons offers products that contribute to the local economy and limit the CO2 footprint by reducing transport.